Case Study

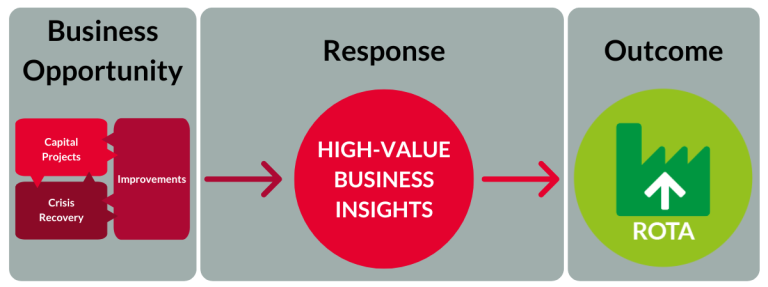

Opportunity

The client requested Bullant’s help when a major grocery customer threatened to delist products due to very poor delivery performance.

Response

Bullant deployed professional resource support to act as the maintenance & reliability manager and help make immediate changes at the manufacturing plant. Bullant also created the following useful business insights with the help of operations personnel at the manufacturing plant;

- A Value Stream Map at the Factory Level which including finished goods inventory buffers at the forward locations. The Value Stream Map confirmed that the root cause of the supply problem was the running efficiency of one of the 6 high-tech packing lines.

- A Process Map and Bullant Filters for the affected line to identify points of highest performance leverage.

- Documented 13 Performance-Centred Improvements that would create the capacity buffer on the line required to service the customer more reliably. These were consolidated into a single Performance Project.

Outcome

A team of Bullant and client personnel carried out the 13 Performance-Centred Improvements in order of priority. The finished goods inventory buffers at the forward locations were replenished and customer delivery performance was returned to acceptable levels within 2 months. The product delisting was averted.