The project is signed and it’s big and complicated!

You’re not responsible for the total business outcome but the project sponsor has made it clear that you are responsible for Scope, Cost and Time (ie. until she says otherwise!). So what do you do with that?

Vaguely you know that you should be thinking about how you’re going to set up your team so that it suits the style of project you’re doing. But you’re not sure how that really translates to the type of contracts you use, what sort of purchasing strategy you should use, how you set up your team, the list goes on.

In this post we examine the different configurations of contracts and in-house management resources that are needed for the different levels of project complexity.

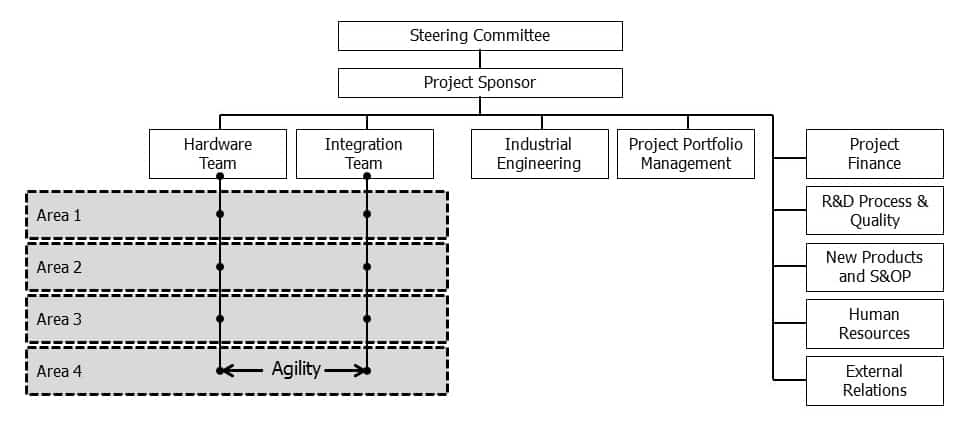

Here is a generic business level, project governance framework for complex projects, such as those found in the Fast Moving Consumer Goods (FMCG) industry.

As you can see for a complex business project there are many fingers in the pie.

The most intense communication occurs between

- The Integration Team (ie. the team of operations, R&D and marketing stakeholders that want to influence the design of the hardware and the way it is integrated into the business), and

- The Hardware Team (ie. those project managers and engineers tasked with getting the project completed on cost, in scope and on time).

There is a lot of agility and flexibility required during communications between these teams.

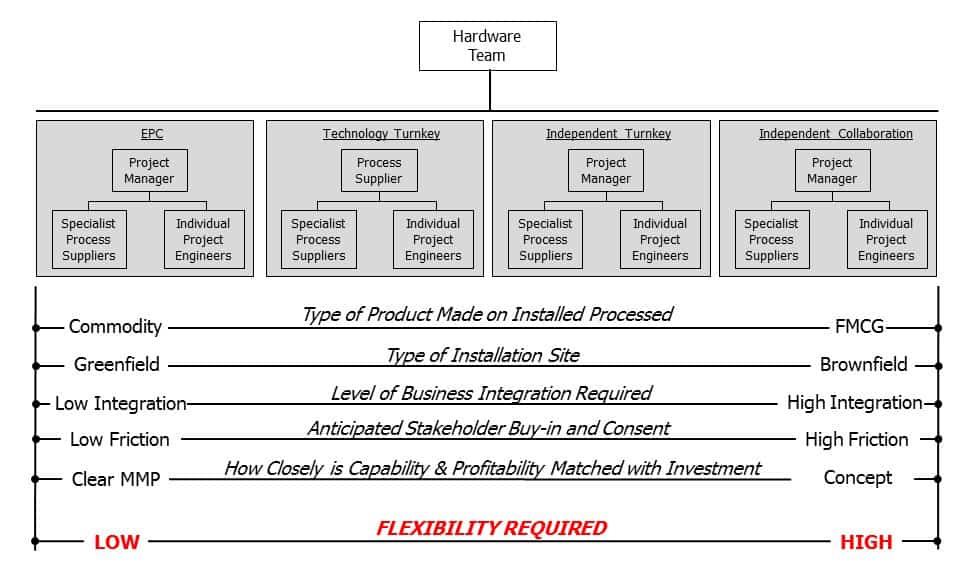

The flexibility required during a project determines how a manager of the hardware team must set up contracts and resources as shown in the graphic below.

Flexibility Required

Before we look at the different contract options lets first review how flexible we need to make the project team. In the graphic above the level of agility required increases as you move from left to right.

Type of Product Made on Installed Process

To the left – you would have something like an iron ore processing system (I know it isn’t food but it gets the point across). While the characteristics of the ore may change from one day to the next (eg. more clay surrounding the ore), the process and the material running through it remain constant.

To the right – you would have something like a production facility containing 200+ different products, requiring 5+ different processing streams, 600+ different material inputs all exhibiting very high levels of variability in terms of both demand and quality.

Type of Installation Site

To the left – is a nice flat, very accessible greenfield site with services to the boundary and no problems with soil quality.

To the right – is a brownfield site in the middle of a production facility. Services are constrained, access is highly restricted and there is even the possibility of product tainting due to fumes created by the machinery required during installation.

Level of Business Integration Required

To the left – there are no significant changes to product or packaging. Logistics and planning systems are adequate, operations are familiar with material inputs and new machinery.

To the right – many new products are being introduced, packaging is being changed on existing products. The project may be predicated on changes to sourcing arrangements (materials and finished products) putting heavy time constraints on the project and requiring coordination with the broader supply team. Material inputs are new and unfamiliar and the processes are new and experimental.

Anticipated Stakeholder Buy-in and Consent

To the left – Key stakeholders have been involved in designing the key elements of the project scope. Not only have the key high-cost elements been agreed but also the operational characteristics of the design have been confirmed with sound, well understood and agreed metrics.

To the right – Key stakeholders do not agree with the design and have given only tacit approval, if any at all. There is much work still required to establish what success looks like particularly in relation to operational metrics. The nature of the business is that requirements are shifting constantly and the project will be expected to accommodate these.

How Closely is Capability & Profitability Matched with Investment

To the left – a lot of work was completed in establishing the Minimum Marketable Project (MMP) before the project was approved. Therefore the capability and profitability of the processes and material inputs have been traded off with the investment required. For more on this see How do I take my complex project from concept to business sign-off?

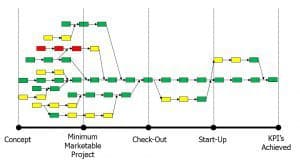

To the right – the project is still in concept stage, as shown in the graphic below, and has been priced and approved on the basis of what the business can afford, with little or no reference to an actual design or hardware cost (this is often a business reality). There are still a lot of experimental (tasks in red below) and trade-off (tasks in yellow) to be completed before the project can be said to have reached the MMP stage. For more on this see The 4 key phases of good project governance.

Contracts and Resources Required

Now that we have some idea of where we need to be on the scale of flexibility required during the project we can now use the Hardware Team graphic above to decide on the style of contracts and resources we need to complete the installation, check-out, start-up and performance testing of the hardware.

If you are managing a large project then it is better to split it into manageable chunks. So for example a project may include a building, services and 3 different types of interconnected processes. Each of these 5 areas will probably have different flexibility needs and therefore require different contracting and resourcing strategies.

Therefore the 5 areas can be viewed as sub-projects and different cantracting and resource strategies can be used for the different sub-projects according the flexibility required.

So referring to the Hardware Team graphic and going from left to right;

Engineer, Procurement and Construction (EPC)

Here the contractor designs the installation, procures the necessary materials and equipment and builds the project, either directly or by subcontracting the work. The attraction for the receiving business is that these contracts are usually fixed price. If there is virtually no flexibility required during project execution then this is a valid approach. If on the other hand a business enters into an EPC expecting, indeed knowing, that they will require a good deal of flexibility to achieve the business outcome of the project then this will probably turn into something of a litigious mess.

Technology Turnkey

This is where you rely on a large, specialised machinery manufacturer to design and manage the vast majority of the project, particularly the process and technology component. All of the surrounding infrastructure can than be contracted using the EPC format, providing there are not many infrastructure implications from an evolving process design.

This approach can work quite nicely for a project requiring some flexibility during the design phase. Particularly if the vendor has had vast experience managing these types of projects using the type of technology required. The main drawback with this approach is that commercial negotiations may be hindered by supply restraints imposed by the vendor (if the vendor specialises in canning equipment then the contract will include his gear).

Independent Turnkey

This is where a provider agrees to manage a project on a cost-plus basis so that scope, time and cost can be adjusted as required. These are usually larger project management businesses with significant internal specialist resources.

The main attraction with using these companies is that they have a level of expertise and client testimonials that gives the impression of reducing risk for the buyer. This may well be the case for the correct sort of project, and indeed they are more flexible than an EPC arrangement or a Technology Turnkey contract.

That said, these businesses still need to recover their overheads. Having specialist technicians on staff, and available all the time, can be quite expensive. Also they rarely offer advice on the operational capability and profitability of a proposed processing system. While they can tolerate some changes in scope, their interest in a project with too much noise starts to subside fairly quickly as they struggle to maintain their margins.

Independent Collaboration

This is where a team of independent specialist are brought together to form an ad-hoc team, lead by a specialist integrator. This is modeled after the agile project management approach and the emphasis here should be 4-fold;

- ensure that the specialist integrator is capable of connecting the project design with the project deliverables. The specialist integrator must be capable assessing the operational capability and profitability of the process design as it evolves and communicating it to the leader of the hardware team.

- select the most experienced and technically capable person for each activity

- ensure that each team member is capable of the agility and patience required in a high-change project environment

- use an agile project management control and review system so that the design adjusts to the needs of your business

The extent to which you use your own staff as integrators or specialists, or contract these tasks to 3rd parties, is determined by the resource and skill level you have in your business and your current project load.

It is only recently that there has been a perfect storm of technology and project management thinking (particularly in the areas of agile project management and project portfolio management) that makes this sort of distributed project management a practical and cost effective reality. For more on this see The 3 big trends that will change project management forever.