Production levelling (or smoothing) is an important part of the Toyota production system. Here we show why production levelling is so important and how it is achieved in the process industry.

To quote Taichi Ohno, considered by most to be the founding father of Lean production:

“On a production line, fluctuations in product flow increase waste. This is because the equipment, workers, inventory, and other elements required for production must always be prepared for peak production.”¹

Heijunka (pronounced hi-JUNE-kuh) is a Japanese word that means “levelling”. Toyota pursue Heijunka (production levelling) as a priority for two reasons;

Minimise Capacity Buffers

The Toyota production system is extremely sensitive to fluctuations in the total volume of cars and trucks made. These shifts are difficult to accommodate in a system in which employees, because of job guarantees are a fixed cost.² This means that labour cannot easily be used as a capacity buffer. Standby labour is a waste in any industry including the process industry and should be minimised. The Japanese just have a bigger motivation to do so.

Minimise Supply Chain Inventory Costs

The Japanese have always understood the benefits that production levelling can have for inventories and suppliers in the total supply chain. They ensure a steady volume of business for their suppliers. That way, the suppliers can utilize employees and machinery much more effectively than in the West, where they are constantly faced with sudden changes in the volume and mix of orders at very short notice. This behaviour causes additional costs and inventories throughout the pipeline due to the well known bull-whip effect.

Obviously this is just as important in the process industry.

So how do you go about production levelling, particularly in the process industry?

Just as for Toyota we need to operate on both the demand and supply side of the sweet spot between the factory and the distributed of finished products, sometimes called the “push-pull interface”. Whatever the name, this is the place where the health of a supply chain can really be assessed.

Starting on the demand side …..

Sense and Manipulate Demand

The aggressive selling system used by Toyota makes the success of Heijunka possible in the Japanese domestic market, while in export markets the Japanese lean producers have enjoyed a cost or quality advantage for thirty years. This has made it possible to cut prices during market slumps in order to keep production volume steady.²

Demand sensing and manipulation have become something of revelation with the advent of on-line sales and the headaches this channel causes for network design and management. The reality is that Toyota have been focusing on this area for some time.

The techniques used in the process industry are not much different to Toyota approach although it should be said that the vagaries of consumer promotions, more aggressive seasonality, difficult and costly changeovers and limited shelf life are all relevant.

Decide on Forecast or Demand Signals

If forecasts signals are more variable than customer demand signals then use demand signals. If the opposite is true then either reduce the variability of demand signals (see previous point and check that inventories are not distorting demand signals) or use forecasts for signalling replenishment.

I’ve seen many definitions of “pull” and often zero forecasts are seen is a prerequisite. More important is that there is a plan for each SKU that brings supply closer to the needs of demand maximising the flow of product to customers. The closer the supply-demand flow conduit then the more that that chain can be described as pull. This may or may not require the use of forecasts.

Make Inventory Buffers Work

Most logistics professionals recognise that there should be an allowance for volatility when sizing inventory buffers. However, in practise whenever a minimum level is breached then both the ERP system and schedulers start expediting behaviour immediately. This nervousness creates a lot of expedite-related expense within the supply chain (eg. premium freight, overtime at warehouses and factories) when in many cases the inventory buffers can be allowed to absorb most of the variation.

This is one of the strengths of the current Demand Driven MRP movement. Planning and execution are clearly separated so that inventory is allowed to perform it’s demand levelling function, absorb much more volatility, and thus extract the maximum value out of the investment in inventory.

If all this demand side work is in place then shifting our focus to the supply side is made so much easier (although supply-side work can be completed in isolation):

Create a Plan for Every Product

Every product is different and here is a list of variables within the process industry that effect the customised plan that’s needed for each product.

- network design

- demand variability

- forecast variability

- average volume

- inventory locations

- factory sequence constraints

- minimum run lengths

- seasonality

- available production capacity

- contribution margin

- changeover costs

- shelf life

- replenishment technique

- Make to order

- Make to stock

- Assemble to order

- Assemble to stock

- demand driven MRP

- forecast driven MRP

- the list goes on

There are many variables involved in deciding the best plan for each product in the process industry. This complexity however makes a plan for every product even more important.

Armed with an understanding of the unique pipeline characteristics of each product we can now turn our attention to formulating a levelled production plan.

Create Product Wheels

Peter King developed the concept of Product Wheels about 10 years ago during and after his time at Dupont.

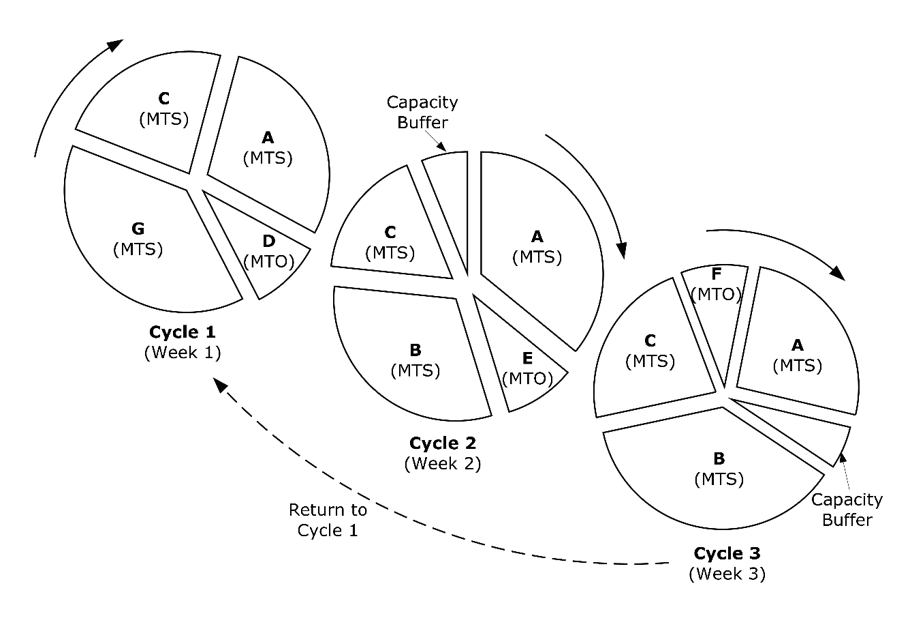

Product Wheel is a visual metaphor for a structured, regularly repeating sequence of the production of all materials to be made on a specific piece of equipment or process.³

The method for creating optimal Product Wheels will be left to a separate post.

I also plan to leave a detailed discussion of the factory-based benefits of Product Wheels for a future post but for the purposes of this article its worth highlighting the main total supply chain benefits;

- Product Wheels formalise the optimum response to the characteristics of each product as it relates to the total supply chain – see all points above.

- Product Wheels assure minimum capacity buffers at the production plants – see first point above

- Product Wheels minimises bullwhip effects both upstream and downstream of the production plants – see second point above

By way of illustration, a set of 3 week long Product Wheels are shown below;

¹ – The Product Wheel Handbook: Creating balanced flow in high-mix process operations, by Peter L. King, Jennifer S. King, CRC Press, 2013.

² – The Machine that Changed the World, by James P. Womack, Daniel T. Jones, Daniel Roos, Free Press, 2007.

³ – Lean for the Process Industries, Dealing with Complexity, by Peter L. King, CRC Press, 2009.