The Theory of Constraints (TOC) is a powerful improvement technology that asserts that any manageable system is limited in achieving its goals by a very small number of constraints. Developed by Dr. Eliyahu M. Goldratt, it provides a useful way to understand and manage complex industrial processes. One of the key concepts of TOC is the classification of factories into four types: V, A, T, and I.

In this post, we will delve into these four factory types and help you identify which one best describes your process factory. Understanding this can lead to more effective factory management and better decision-making.

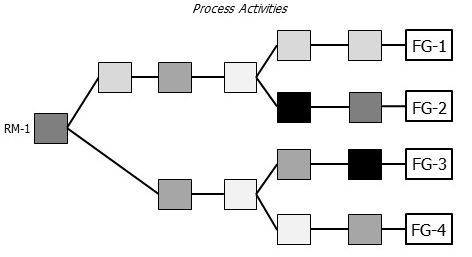

1 V-Type Factory

The flow of material in V-plants, such as meat rendering plants, cheese plants, rice plants, and steel manufacturers, is one-to-many. These plants take one raw material and produce multiple final products. For example, a steel mill utilizes iron ore to manufacture a variety of steel products.

The main challenge lies in efficiently managing the diverging processes to meet the demand for each output without overwhelming the shared input resources. Additionally, V-plants face the issue of “robbing,” where an operation immediately after a diverging point takes materials intended for a different product or operation.

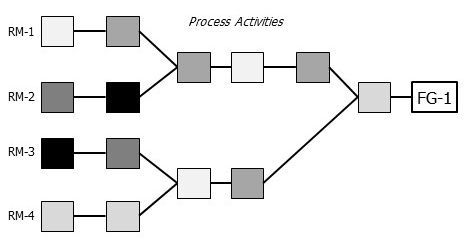

2 A-Type Factory

The A-type factory operates with a workflow that resembles the shape of the letter “A” ;-). In this type of factory, multiple inputs converge to create a final product, much like a car assembly line where various components are brought together to form a finished vehicle.

The primary challenge in V-type factories is to synchronize the different input streams, ensuring that they come together in the right way at the right time. This is typically accomplished by strategically using buffers to minimize the risk of stoppages caused by starvation.

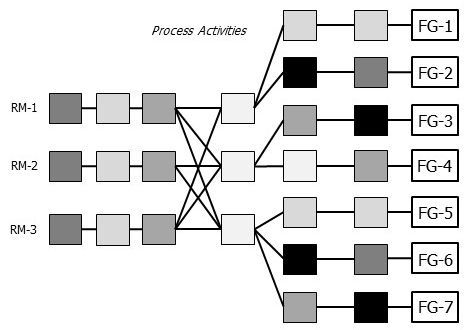

3 T-Type Factory

T-type factories, also known as T-plants, operate by processing multiple inputs separately, combining them, and then separating them into different outputs. For instance, a furniture manufacturer may independently source wood, metal, and fabric, combine them to create furniture, and then distribute different products to various locations. Similarly, a food manufacturer may need to combine different premade foods into one product with varying packaging sizes.

The main challenge lies in coordinating the separate inputs and outputs while maintaining efficiency in the central process. T-plants face the synchronization issues encountered by A-plants (where parts may not be available at converging lines) and the robbing problems of V-plants (where one assembly steals parts that could have been used elsewhere). Consequently, T-plants are the most complex among the different plant types, requiring a delicate balance in terms of coordination, scheduling, performance, and waste control.

In T-plants, synchronization issues create a coordination challenge, making it akin to a black art. Simplification becomes crucial in managing T-plants. They can be found in environments where product mixes are complex and yet there is a competing need to minimize fixed assets.

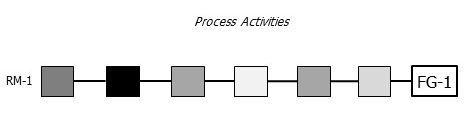

4 I-Type Factory

Lastly, the I-type factory, or I-plant, is characterized by a linear flow where an input goes through several stages of transformation to become an output. For example, in a bakery, raw ingredients are taken through a series of steps such as mixing, kneading, and baking to produce bread.

The main challenge in I-type factories is ensuring a smooth flow through all stages of production to prevent bottlenecks. However, in reality, achieving this is often difficult, and the capacity is determined by the slowest operation, known as the Capacity Constrained Resource (CCR) or more commonly referred to as the “Drum”.

To address this challenge, managed buffers can be implemented to ensure that the Drum is always fed with material and that the downstream path remains clear.

To identify the specific challenges within your manufacturing process and implement the most effective solutions, it is crucial to have a clear understanding of these four types of factories. By aligning your strategies with the unique characteristics of your factory type, you can improve operational efficiency more effectively and apply improvement and innovation techniques with greater precision.

Remember, there’s no one-size-fits-all approach in operations management – what works best depends on the specific nature of your factory. So, take the time to understand your operations, identify your factory type, and adopt strategies that will help you overcome your unique constraints.