Supply chains that have evolved using Enterprise Resource Planning (ERP) or Supply Chain Management (SCM) systems should not be the only point of reference when designing a new supply network.

Good supply network design is an iterative process focusing on both maximum flow and minimum cost.

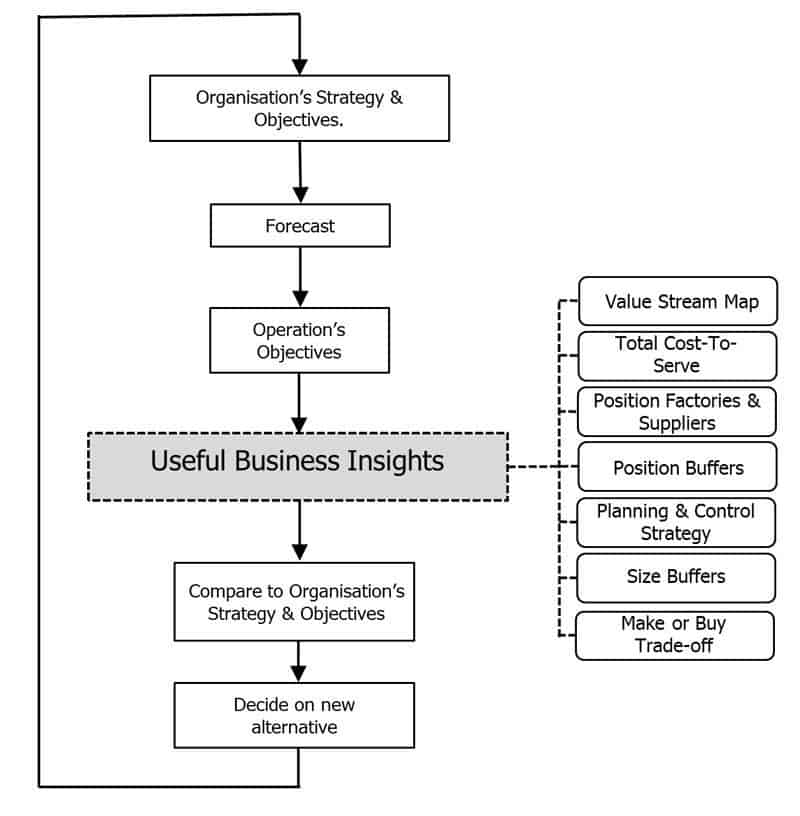

This iterative process starts at the organisation’s business strategy and consists of the following;

- Convert the organisation’s strategy to operational objectives

- Create a value stream map

- Focus on flow and total cost-to-serve

- Scope and position your factories and suppliers

- Position your buffers

- Decide on your planning & control strategy

- Size your buffers

- Make or buy trade-off

- Iterate

1. Convert the organisation’s strategy to operational objectives

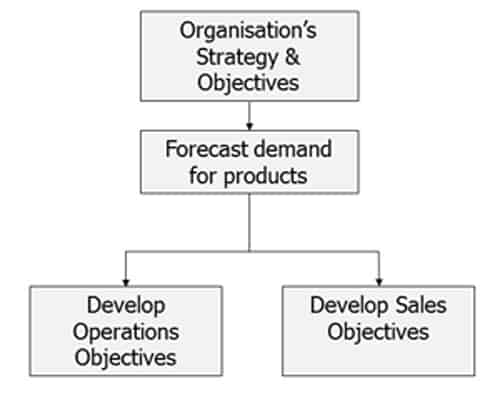

Exactly how an organisation’s strategy should get converted to sales and operations objectives is up to the individual organisation. The graphic below depicts one possible approach.

An organisation’s strategy & objectives can include three general competitive strategies;

- Cost Leadership – A company using this strategy must ensure that it has well developed systems for monitoring and controlling costs, productivity and inventory levels.

- Differentiation – An organisation’s ability to provide a product that differs in some way from the competition. Includes customer service, lead times, quality, demand responsiveness/agility, short product life cycles.

- Market Segmentation – this segmentation could be based on a customer group, product line, geographical location.

An aggregate demand forecast should contain both statistical and judgemental forecasts with the following issues being particularly relevant for supply chain design in the process industry;

- Seasonality – the extent to which outbound demand (e.g. mineral water sales increasing in summer) and inbound supply (eg. the supply of grapes in the wine industry) varies markedly during the medium term.

- Product Life Cycles – how often will products be revitalised to maintain customer interest and demand

- Sudden Volume Changes – How often will demand increase or decrease quickly (e.g. major supply contract changes)

2. Create a Value Stream Map

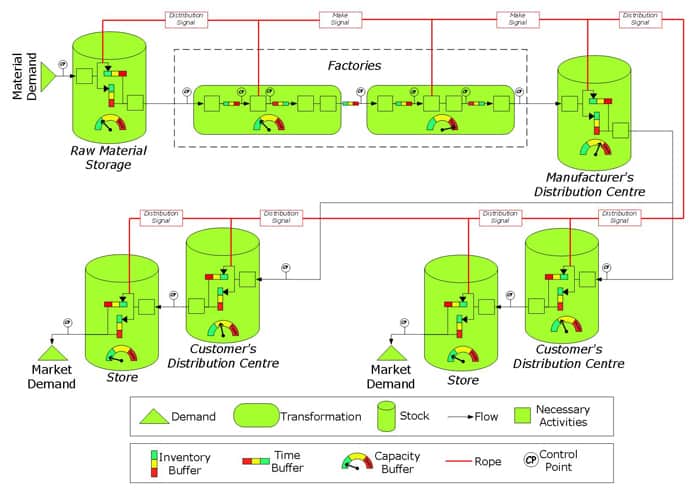

The starting point for supply network design should be a value stream map which includes all facets of operational flow.

We have developed a value stream mapping process for the process industry using what we call Flow Consoles. Flow consoles are traditional value stream maps that include important information on capacities and utilisation.

The basic building blocks of a Flow Consoles are summarised in our article 10 high-powered building blocks that change the way you look at your complex supply chain.

A simple flow console for a retail supply chain is shown below.

3. Focus on Flow and Total Cost-to-Serve

The metrics shown at the detailed level of any value stream map are leading flow metrics. When we say flow we mean the flow of profit. So these leading metrics identify opportunities for the higher flow of profit and, by definition, higher financial performance. Hence,

- Increasing flow ALWAYS increases profit

- Reducing costs DOES NOT ALWAYS increase profit!

Therefore, the greatest benefits accrue when flow metrics from a value stream map and information on the total cost-to-serve are used and optimised together.

4. Scope and Position your factories and suppliers

This is where we move to a finer level of detail and no one approach can possibly satisfy the strategic needs of every organisation. So when positioning and scoping the capability of suppliers and company-owned factories here are some questions that should be asked;

- Should factories be located near the customer or near to raw materials? – this is usually a question of transportation costs but can be influenced by the competitive strategy such as freshness claim.

- Should there be one large facility or several small ones? – Large facilities generate economies of scale but agility and supply chain risk are also important considerations.

- How vertically integrated should the organisation be? How important is it for the factory to be located near resources that eliminate risks caused by middle-man operations?

- Should the workforce be skilled or unskilled? Should jobs be specialised? Is an appropriate workforce located in a reasonable radius? What are the prevailing labour rates in the area or country?

- Are there any local environmental considerations such as supply of services and opportunity for expansion? Are there transportation issues such as congestion, road condition and noise curfews?

- Are there government incentives or disincentives?

5. Position your buffers

There are three types of buffer in a supply network; Capacity, Time and Inventory.

- Capacity Buffer Position – The location of the factories and suppliers (above) determine the location of their capacity buffers. There are capacity buffers in warehouses but their position is determined by the position of time and inventory buffers.

- Time and Inventory Buffer Positions – The following 3 factors have an influence over the position of both time and inventory buffers;

- The extent to which inventories are being used to decouple parts of the supply network to minimise customer leadtimes and mitigate particular supplier risks.

- How the benefits of stock aggregation are being deployed on both the inbound and outbound side of the factories and suppliers

- The type of hub and spoke distribution network most suitable for the location of the customers and the factories including Hub at source, Hub/RC Combo, Multi-hub and hybrids.

6. Decide on your Planning & Control Strategy

Most supply chains in the process industry are using a hybrid of forecast-driven and demand-driven planning and control tactics. Lean practitioners have a love-hate relationship with forecasts and this is appropriate. Forecast-driven MRP systems always push material into a supply chain however, forecasts are crucial to medium and long-term planning processes.

Demand-driven planning and control techniques are evolving quickly. The idea of “flowcasting” pure demand through the distribution system all the way from the source (i.e. the retail store for a retail supply chain) is theoretically possible and being enabled by more sophisticated re-planning systems. For the demand driven approach to be successful however, it must include a sophisticated understanding of buffer positioning and sizing.

In any case, whether forecast-driven and/or demand-driven planning tactics are being deployed, there are 4 considerations;

- What are the optimum order quantities for each material and product based on the changeover costs and inventory holding costs?

- What load leveling/sequencing techniques are to be used at each factory or supplier? Based on these sequencing techniques, what are the expected replenishment leadtimes for each product?

- Based on average demand and anticipated supply and demand variability, what products will be Make To Order, Make To Stock, Finish To Order, etc?

- How will seasonality, if it exists, be managed? Will it be managed using capacity buffers, inventory buffers or a combination of both? Where will these buffers be located?

7. Size your buffers

- Capacity Buffer Sizing – As a general rule of thumb there should be about 15% capacity buffer (or sprint capacity) at each factory or warehouse on standard workforce shift patterns. This is required to absorb both supply and demand variability (even with good load leveling). Businesses with significant seasonality or exposed to sudden increases in demand (e.g. contract packing) should be fully aware of how their capacity buffers can be flexed with the manipulation of assets and workforce.

- Time Buffer Sizing – Time buffers external to a transformation process (see graphic above) are used to manage Make-To-Order products and materials and are sized according to anticipated lead times, supply cycles, and customer tolerance times. Time buffers (Work In Process) inside a transformation process are sized according to the expected statistical interplay of capacities, efficiencies and schedule sequences.

- Inventory Buffer Sizing – Inventory buffers are used to manage Make-To-Stock products and materials (see planning and control tactics above). Inventory buffers can be sized using;

- The Lean approach to inventory buffer sizing.

- The Demand Driven approach to inventory buffer sizing.

8. Make or Buy Trade-off

Any borderline SKU’s in terms of profitability, can be reviewed for potential outsourcing. There are 2 important considerations when deciding whether to make or buy products;

- The decision must be made on the basis of total cost to serve (e.g. an outsourcing opportunity may look good based on ex-supplier costs but be unacceptable from a total cost-to-serve point of view)

- Production people should be involved in the decision to ensure the best possible conversion cost reduction at the company-owned factory.

9. Iterate

Finally, supply network design is an iterative process (shown below).